The automotive industry has seen significant advancements in recent years, with new technologies and materials being introduced to enhance performance, safety, and sustainability. One such material that has gained prominence is PA6 6 GF25, a glass fiber-reinforced polyamide commonly used in automotive engineering. Its unique properties make it an ideal choice for various applications within the industry.

PA6 6 GF25 is renowned for its exceptional strength-to-weight ratio, making it incredibly lightweight yet highly durable. This material offers excellent mechanical properties such as high tensile strength, stiffness, and impact resistance, enabling engineers to design safer vehicles without compromising on performance. Additionally, PA6 6 GF25 exhibits excellent dimensional stability and low creep characteristics even under extreme temperatures and constant loading conditions.

Overview of PA6 6 GF25 and its properties

PA6 6 GF25, also known as polyamide 6.6 with 25% glass fiber reinforcement, is a widely used material in the automotive engineering industry. This composite material combines the excellent mechanical properties of polyamide with the added strength and stiffness provided by the glass fibers.

One of the key properties of PA6 6 GF25 is its high tensile strength. The addition of glass fibers significantly enhances the material’s ability to withstand heavy loads and resist deformation under stress. This makes it ideal for applications where structural integrity is crucial, such as in automotive components like engine covers, intake manifolds, and brackets.

Another important property of PA6 6 GF25 is its excellent dimensional stability. The presence of glass fibers minimizes shrinkage and warping during processing, ensuring that parts made from this material maintain their shape and fit accurately within assemblies. Additionally, this composite material exhibits good thermal resistance and can withstand elevated temperatures without significant degradation or loss of performance.

Overall, PA6 6 GF25 offers a balance between strength, durability, and cost-effectiveness that makes it an attractive choice for various automotive engineering applications. Its mechanical properties make it suitable for demanding environments while its dimensional stability ensures consistent performance over time.

Lightweighting: Reducing vehicle weight for better efficiency

One of the key applications of PA6 6 GF25 in automotive engineering is lightweighting, which involves reducing the weight of vehicles to improve fuel efficiency and overall performance. PA6 6 GF25, also known as nylon 66 with glass fiber reinforcement, is a high-performance thermoplastic that offers excellent mechanical properties and strength-to-weight ratio. By using this material in various components like engine parts, structural reinforcements, and body panels, automakers are able to significantly reduce the weight of vehicles without compromising on safety or durability.

The use of PA6 6 GF25 in automotive lightweighting helps to achieve better fuel economy by reducing the vehicle’s overall mass. With lighter vehicles, less energy is required to accelerate and maintain speed, resulting in improved fuel efficiency and lower emissions. Additionally, the superior mechanical properties of this material allow for thinner walls and reduced thicknesses in components without sacrificing strength or stiffness. This not only contributes to weight reduction but also enables more efficient manufacturing processes while maintaining optimal performance levels.

Furthermore, the incorporation of PA6 6 GF25 into automotive engineering promotes sustainability by reducing the environmental impact associated with vehicle production and operation. The lightweight design results in reduced consumption of raw materials during manufacturing while improving energy efficiency during vehicle usage. Moreover, lighter vehicles put less strain on infrastructure such as roads and bridges due to reduced loadings.

Mechanical Properties: Enhancing strength and durability

One of the key aspects in automotive engineering is to enhance the strength and durability of various components. To achieve this, engineers often turn to materials like PA6 6 GF25, a type of glass fiber reinforced polyamide. This material has excellent mechanical properties that make it highly suitable for automotive applications.

PA6 6 GF25 offers superior tensile strength, which means it can withstand high levels of stress without breaking or deforming. This makes it ideal for use in parts like engine brackets, suspension systems, and steering components where strong structural integrity is crucial. Additionally, this material also exhibits great impact resistance, allowing it to absorb energy during collisions or sudden shocks without experiencing permanent damage.

Moreover, PA6 6 GF25 possesses excellent endurance and fatigue resistance properties. It can withstand repetitive loading cycles over extended periods without undergoing significant degradation in performance. This ensures that automotive components made from this material will last longer and require fewer repairs or replacements over their lifespan. Overall, the mechanical properties of PA6 6 GF25 play a vital role in enhancing the strength and durability of automotive parts while maintaining overall safety on the road.

Thermal Properties: Withstanding high temperatures in engine compartments

One of the key factors that determine the suitability of a material for use in engine compartments is its ability to withstand high temperatures. In automotive engineering, PA6 6 GF25 has emerged as a popular choice due to its excellent thermal properties. This reinforced polyamide material possesses a high melting point, allowing it to retain its structural integrity even under extreme heat conditions.

Additionally, PA6 6 GF25 exhibits low thermal expansion, which means that it does not significantly change in size or shape when exposed to fluctuating temperatures. This property is crucial in engine compartments where temperature variations can be rapid and substantial. The material’s resistance to thermal degradation also ensures long-term durability and performance.

Moreover, PA6 6 GF25 offers good flame retardancy, making it an ideal material for applications in close proximity to hot components within the engine compartment. Its ability to withstand high temperatures without compromising safety makes it an attractive option for various automotive engineering applications such as intake manifolds, air ducts, and engine covers.

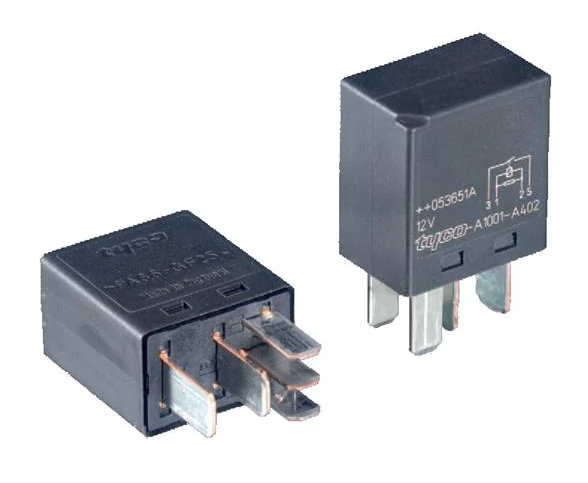

Electrical Properties: Insulation and conductivity benefits

In automotive engineering, the use of PA6 6 GF25, a type of glass fiber-reinforced nylon, offers several benefits in terms of electrical properties. One key advantage is its excellent insulation properties. The glass fibers embedded within the material act as a barrier against electric current, preventing any leakage or short-circuiting. This insulation property is crucial in automotive applications where electrical components are in close proximity to each other and need to be protected from unwanted electrical interference.

Furthermore, PA6 6 GF25 also exhibits good conductivity characteristics when compared to other materials used in automotive engineering. While it may not have the same high level of conductivity as metals like copper or aluminum, it still allows for efficient transmission of electricity across various components and connectors. This makes it an ideal choice for applications that require reliable electrical connections, such as wiring harnesses and connectors within vehicles.

Overall, the combination of excellent insulation properties and adequate conductivity makes PA6 6 GF25 a versatile material for various electrical applications in automotive engineering. Its ability to provide reliable insulation helps protect sensitive electronic components from damage caused by external factors or electromagnetic interference. At the same time, its conductivity ensures efficient flow of electricity throughout the system for optimal performance.

Noise Reduction: Minimizing vibrations and sound levels

One important application of noise reduction in automotive engineering is the use of PA6 6 GF25 (polyamide 6.6 with 25% glass fiber) in various components. This material offers excellent mechanical properties, such as high stiffness and strength, which can help to minimize vibrations and reduce sound levels within the vehicle. By using PA6 6 GF25 in parts like engine mounts, suspension components, and body panels, automakers can effectively dampen vibrations that would otherwise be transmitted throughout the vehicle.

In addition to its mechanical properties, PA6 6 GF25 also has good acoustic insulation properties. When used in automotive applications, this material can absorb and block sound waves, reducing noise levels inside the cabin. This is particularly important for electric vehicles (EVs), where there is less engine noise to mask other sources of noise. By utilizing PA6 6 GF25 in areas such as wheel arch liners and underbody panels, automakers can create a quieter driving experience for EV owners.

Overall, the use of PA6 6 GF25 in automotive engineering enables effective noise reduction by minimizing vibrations and reducing sound levels. Its mechanical properties help to dampen vibrations from various sources within the vehicle, while its acoustic insulation capabilities contribute to a quieter cabin environment. As automakers continue to prioritize comfort and refinement in their vehicles, materials like PA6 6 GF25 play a crucial role in achieving these goals.