Central lubrication systems are an essential component in the smooth functioning and longevity of machinery across various industries. These automated systems have gained immense popularity due to their ability to optimize machinery performance, minimize downtime, and enhance maintenance efficiency. By delivering precise amounts of lubricant directly to the critical components of a machine, central lubrication systems ensure that friction and wear are reduced to a minimum, resulting in improved overall performance and extended operational life. This article explores the numerous advantages offered by central lubrication systems, highlighting how they contribute to increased productivity, reduced maintenance costs, and enhanced safety within industrial settings.

The ISOHITECH Central Lubrication System is a state-of-the-art solution for efficient and automated machinery lubrication. This advanced system ensures precise and consistent grease distribution to critical components, enhancing equipment performance and longevity. Its centralized design simplifies maintenance, reducing manual intervention and downtime. The system is equipped with smart monitoring capabilities, enabling real-time data on lubrication levels and performance, ensuring timely refills and preventing lubrication-related issues. ISOHITECH Central Lubrication System is a reliable and cost-effective choice for industries seeking to optimize machinery performance, minimize wear and tear, and streamline maintenance processes.

What are central lubrication systems?

Central lubrication systems are mechanical devices that distribute lubricants to various parts of machinery in a centralized manner. These systems are designed to ensure that all the moving parts of a machine receive adequate lubrication, thus reducing friction and wear. One of the key advantages of central lubrication systems is their ability to enhance machinery performance. By providing consistent and precise amounts of lubricant to the different components, these systems can optimize the efficiency and productivity of machines, ultimately leading to improved overall performance.

Moreover, central lubrication systems also contribute significantly to maintenance efficiency. With these systems in place, manual lubrication tasks are eliminated or reduced, saving time and effort required for routine maintenance activities. The automated distribution of lubricants by central lubrication systems not only simplifies maintenance procedures but also helps prevent human errors that may occur during manual greasing. Additionally, by ensuring proper and timely lubrication throughout the machine’s lifespan, these systems can extend equipment life and reduce downtime caused by unexpected breakdowns or repairs.

In summary, central lubrication systems play a crucial role in enhancing both machinery performance and maintenance efficiency. Their ability to provide consistent and precise amounts of lubricant ensures optimal functioning of machines while minimizing wear and tear on their components. Moreover, with automated distribution capabilities, these systems simplify routine maintenance tasks and help prolong equipment life by preventing unexpected breakdowns or repairs due to inadequate or improper lubrification.

Advantages of central lubrication systems

Central lubrication systems provide numerous advantages in terms of enhancing machinery performance and maintenance efficiency. Firstly, these systems ensure a consistent and precise application of lubricants to all necessary points within the machinery. This uniform distribution of lubrication helps to reduce friction and wear on moving parts, thereby increasing the overall lifespan of the equipment.

Additionally, central lubrication systems offer time-saving benefits during maintenance procedures. With a centralized system in place, technicians can easily access and service all lubrication points from one central location. This eliminates the need for individual manual oiling or greasing of each component, saving valuable time that can be redirected towards other maintenance tasks.

Furthermore, central lubrication systems contribute to improved safety in the workplace. By automating the process of lubricating machinery, workers are less exposed to potential hazards associated with direct contact with rotating or moving parts during manual lubrication procedures. This reduces the risk of accidents and injuries, promoting a safer working environment for employees.

Improved machinery performance

One of the key aspects of improved machinery performance is the implementation of central lubrication systems. These systems are designed to deliver precise amounts of lubricant to the different parts and components of a machine, ensuring optimal functioning and reducing friction. By regularly lubricating the moving parts, central lubrication systems help minimize wear and tear, prolonging the lifespan of the machinery.

In addition to enhancing performance, central lubrication systems also contribute to increased maintenance efficiency. With a centralized system in place, it becomes easier for maintenance personnel to access and maintain all the necessary lubrication points. This reduces downtime as well as the time required for manual lubrication tasks. Moreover, these systems often come equipped with monitoring capabilities that allow operators to track fluid levels remotely or even set up automated alerts when maintenance is needed.

Overall, by improving machinery performance and streamlining maintenance processes, central lubrication systems offer significant advantages for businesses across various industries. They not only enhance productivity but also reduce costs associated with repairs and replacements while ensuring optimal operation of critical equipment.

Increased maintenance efficiency

One of the key benefits of central lubrication systems is that they significantly increase maintenance efficiency. By automating the lubrication process, these systems eliminate the need for manual lubrication, saving both time and effort for maintenance personnel. This allows them to focus on other important tasks and improves overall productivity.

Additionally, central lubrication systems ensure precise and consistent delivery of lubricants to all the necessary parts of machinery. This eliminates the risk of under or over-lubrication, which can cause premature wear and tear or even equipment failure. By providing optimal amounts of lubricant at regular intervals, these systems help extend the lifespan of machinery and reduce maintenance costs in the long run.

Furthermore, central lubrication systems streamline maintenance operations by simplifying the monitoring and control processes. These systems are equipped with sensors and controllers that provide real-time data on lubricant levels and performance parameters. This enables maintenance personnel to easily track and assess machine conditions, making it easier to detect potential issues early on and take proactive measures to prevent breakdowns or malfunctions.

Extended machinery lifespan

One major advantage of central lubrication systems is the ability to extend the lifespan of machinery. By ensuring that all moving parts are properly lubricated, these systems help reduce friction and wear, which can significantly increase the longevity of equipment. This is particularly beneficial for heavy-duty machinery that is subject to constant use and high levels of stress.

Furthermore, central lubrication systems also minimize the risk of breakdowns and unplanned downtime. Regular and automated lubrication eliminates the need for manual application, reducing human error and ensuring consistent coverage across all components. This not only improves overall performance but also reduces maintenance requirements, as well as associated costs in terms of repairs and replacement parts.

Overall, by extending machinery lifespan through proper lubrication, central lubrication systems offer a cost-effective solution for businesses looking to maximize their equipment’s operational efficiency while minimizing downtime and maintenance expenses.

Reduced downtime and costs

Reduced downtime and costs are two major benefits of using central lubrication systems in machinery. By automatically delivering the right amount of lubricant to various parts of the equipment, these systems ensure optimal performance and minimize the risk of breakdowns or failures. This ultimately leads to reduced downtime as there is less need for manual lubrication and maintenance interventions.

Moreover, central lubrication systems help in controlling costs associated with machinery maintenance. With these systems in place, businesses can avoid over-lubricating or under-lubricating machines, which can cause excessive wear and tear or premature failure respectively. Additionally, by ensuring a proper level of lubricant is supplied at all times, these systems help extend the lifespan of machine components, reducing the frequency of replacements and repairs. As a result, companies can effectively manage their maintenance budgets and allocate resources more efficiently.

In summary, central lubrication systems contribute to enhanced machinery performance by reducing downtime through automated lubrication processes while also helping organizations control costs by optimizing maintenance intervals and extending equipment lifespan.

Types of central lubrication systems

There are several types of central lubrication systems that can be used to enhance machinery performance and maintenance efficiency. One type is a single-line lubrication system, which uses a centralized pump to distribute oil or grease through a network of pipes and valves to various machine components. This type of system is commonly used in industrial applications where multiple points need to be lubricated.

Another type is a dual-line lubrication system, which operates similarly to a single-line system but uses two separate lines for the distribution of oil or grease. This allows for greater control over the amount and timing of lubricant delivery to different machine parts. Dual-line systems are often used in heavy-duty machinery that requires precise lubrication.

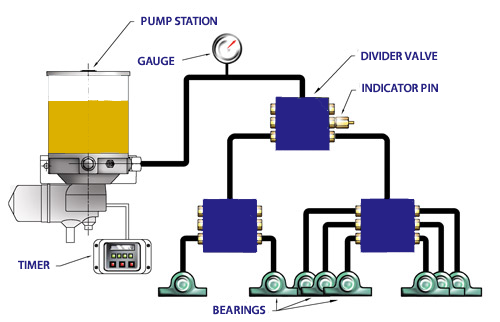

A third type is a progressive or divider block system, which utilizes multiple outlets connected to a central pump. The pump delivers lubricant in stages, with each outlet receiving an incrementally increasing amount of lubricant. This ensures that all machine components receive the necessary amount of lubrication without any excess or waste.

Overall, these different types of central lubrication systems offer various advantages such as improved machinery performance, reduced downtime for maintenance, and extended equipment lifespan.